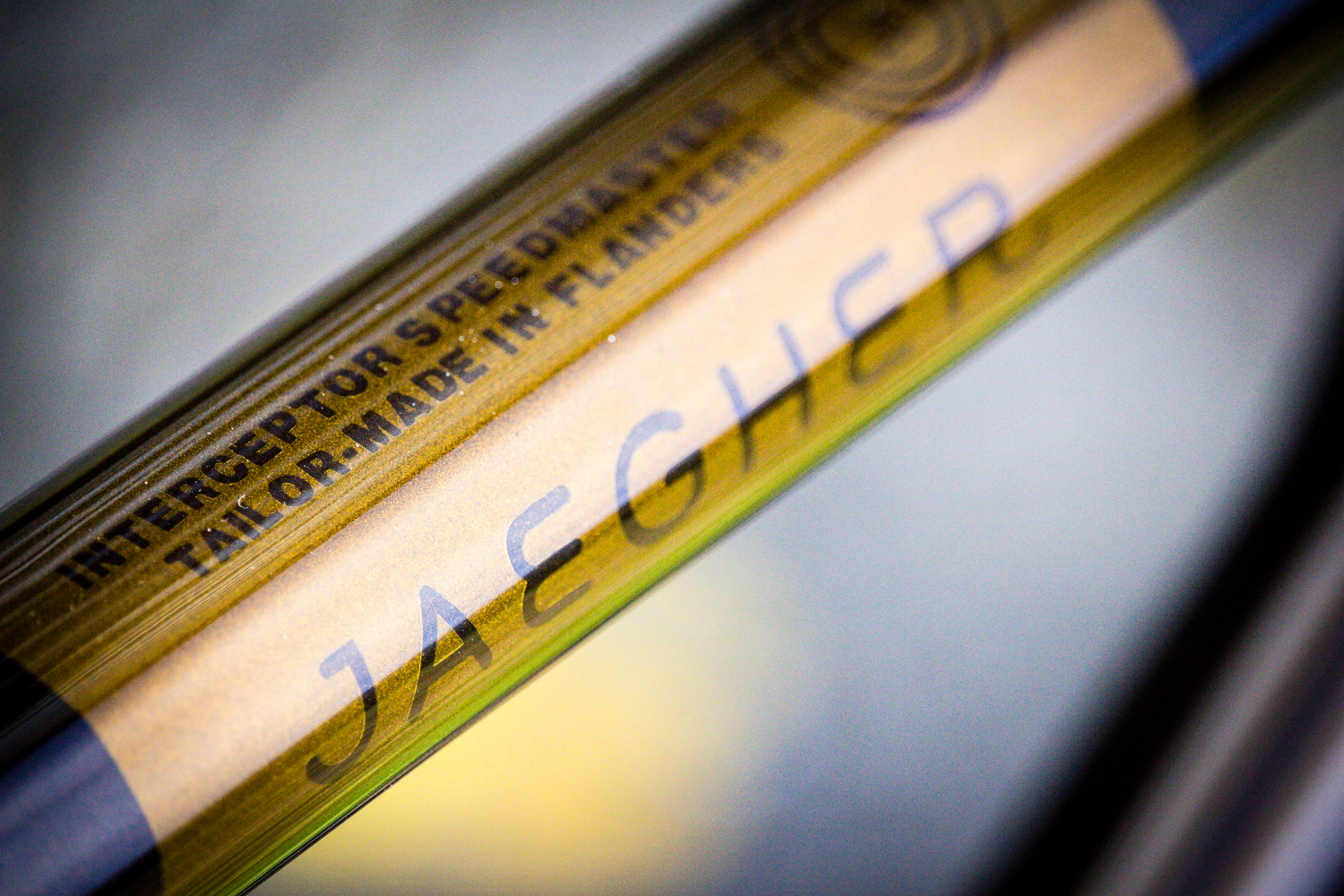

Insider Rides: Brett’s Jaegher Interceptor Speedmaster

I’m an impatient type of guy, mostly. I’ll lie in bed thinking about something that I need to do tomorrow, but jump up and do it right now. If it can be done inside, of course, I mean I’m not heading out to change the oil in the car or anything. So waiting for a new bike should really render me a ball of anxiety and stress thrown at a racquet of highly-strung agitation volleyed back with vehement force. “Good things come to those who wait” wouldn’t be at the top of my mantra list, if such a thing was ever entertained.

The beautiful example of fine steel craftsmanship you see before you now, had a journey of almost two years from thought, to concept, to inception, to materialism. After I’d gone through a similar process a couple of years earlier for my dream road bike, I was ready to add another “last bike ever” to my stable, and I knew exactly where it would come from. An idea for a steel gravel/all-road machine was floated via email with my friends at Jaegher Cycles in West Flanders, Belgium. My collaborator on my road bike project, Steven, was in the process of moving on and I started the process with my new co-conspirator Kurt. The master of the TIG torch Diel would again be creating the magic with the tubes. We had the plan.

The brief was clear if not concise, and we played around with several ideas of what this bike would be, and how it would be used. Mainly I wanted to be able to ride it like my Interceptor road bike, which saw a little too much gravel for such a pristine machine. It handled everything thrown at it though, so the geometry numbers would stick fairly close to that with a slightly more relaxed head angle. As it would see more off-road action, we needed room for big rubber in both 700c and 650b options, disc brakes, tapered head tube and thru-axles.

I still had the vision that it would be a road bike with some dirt capability, and I was set on keeping the running gear firmly in the Campagnolo camp, as per my road bikes. After a few questions with my friend/enabler Joshua in Italy, he threw a spanner in the works by suggesting we go electronic, and a Super Record EPS groupset was on its way to Flanders, along with some Zonda DB wheels. This was going to be a top-tier build of a level that I’d never anticipated.

We coordinated the details with Kurt and we had our template for the frame. I was prepared to wait as long as it took, as Diel’s mastery was in high demand and I was more than happy to hold my place in the queue. A couple of weeks later, Kurt told me that they were building my frame quicker than expected so they could show it at Eurobike, it being their very first gravel bike build and that sector of the market creating a lot of bike-show buzz. Sounded good to me!

The tubing they suggested was Columbus Spirit, just like my road bike, but specially ovalised by the Italian tubemakers to add stiffness for Jaegher’s Flymaster road bikes, formerly labelled as Superstiff. The tubes feel almost as if they are hexagonal, but isn’t immediately apparent to the naked eye. Running your hands over and around them reveals the shaping a bit more, and in the right light they allow the paint to highlight it with a bit of ‘pop’. For the seat tube, Jaegher uses Columbus Life for a bit more strength in that area.

The agonising I went through choosing the paint colour for my previous build was given over to the paint shop, with a brief of “surprise me”. When I pulled the frame from its box my jaw dropped and my eyes popped when they feasted on the dark chocolate metallic flecked finish with gold fleck lettering and accents. The kind of surprise I could never had imagined.

As it was Diel’s first foray into such a bike, he went with a set of pre-fabricated rear dropouts from Paragon Machine Works from California, with a 142×12 spacing for the thru-axle. These use a bolt-on hanger and dropout system which can be easily replaced in the event of damage.

The bike made its way to Eurobike, and thinking I was still having some say in the colour, I suggested that the pearl white that I spotted on a bike at the show would be a good option. “That’s your bike” said Kurt, and I was expecting that to be the final hue. I was more than happy with that.

Post mounts for the hydraulic calipers are optimised for 160mm rotors, which were always the choice over 140mm for a bit more bite in the dirt.

This is where things started to get a little whacky. As my EPS gruppo was still in transit to Jaegher, and the rush was on to get it ready for Eurobike, the crank which they built the bike around was a Shimano 2x for the Di2 build to be displayed. No problem, until the Campa crank turned up and it was discovered that it had a lot less Q factor and clearance was minimal to say the least. Diel would have to modify the chainstays to accomodate it, but there’d be another delay for that and a re-paint. I was still happy to wait but was itching to get my hands on it and a leg over after the sneak peek from the trade show.

Up front was a nice bonus of an ENVE carbon fork, with massive clearance for tyres up to 650b x 2.1 or possibly bigger, judging by the real estate still between tyre and crown. The gold treatment for the hose guide is one of those small touches that make a custom bike that much more custom.

After the stays were indented to keep their straight lines and stiffness but to allow the crank a free rotational path, Kurt went about assembling the bike at last. As I was planning to be in Europe in their Spring, I’d thought about waiting to pick the bike up then. But that was still four or five months away, and I wanted to ride it in our summer in preparation for a stupidy-long gravel race that my mates were putting on. I suggested sending the groupset and the cockpit––which my friends at fi’zi:k in Italy had sent to Belgium––as a seperate package to hopefully avoid some taxes and import duty. A cunning plan that was about to go horribly wrong.

After a month or more of no parts showing up, we started to get worried about their whereabouts and began making enquiries with Belgian Post and NZ Customs. Nothing at this end, and B-Post were playing pretty dumb also. After weeks of investigation and frustration, the verdict was that they had simply been ‘lost’. Not the answer we wanted to hear, and even with Kurt taking it all the way to the ombudsman we were still left empty-handed and down a whole lot of expensive parts. Some asshole Belgian postal-cyclist has some nice bits I’m sure. Luckily, the frame, fork and wheels were still in Kurt’s safe hands, and that’s where I instructed them to stay, especially now as the five months til Spring had shrunk to about two. I was going to make sure this bike made it back to NZ with me, or die trying.

A painted-to-match ENVE stem was a nice surprise from Jaegher. My preferred fi’zi:k bars and tape hold the Di2 levers.

In the meantime I had a frame, fork and wheels, a trip to pay for and not much else. Another EPS groupset was financially unviable, and a mate suggested a Shimano Di2 build with a 1x drivetrain to keep costs down, especially as XT derailleurs were going cheap and I had a wide range cassette already. Another friend thought he had some shifters to donate but unfortunately they didn’t materialise, but I committed to the build and was helped out by the guys at Shimano NZ with the levers and brakes. I wanted some bling in the crankset, so had an Easton EC90SL carbon beauty shipped from the States to my base in France. I would take over the rest of the parts I needed and build the bike there. It was starting to look like this thing might actually get off the ground after all!

The curse of airline travel struck with a chunk of paint taken from the fork from the bike bag retention system. But this is a bike that is ridden and there’s already a few heartbreaking chips appearing and more to come no doubt.

I was lucky enough that local fi’zi:k distributor PRV was clearing out some parts, so I got a great deal on some alloy R3 bars, R1 carbon seatpost and and R3 stem, and I picked up an Aliante Versus saddle for 20 clams off Bike Shelf. A set of long-term test Hunt Adventure Sport 650b wheels (review coming) were also thrown in the bag with some Byway 47c tyres from WTB. All set for the build, I arrived in France ready to get to work. Fuck the jetlag, I was up at 7am the day after arriving to hop the train to Ghent and meet up with Kurt and finally meet the frame. After a run-in with an over-officious French train conductor about the bike box, I finally had the steel in my hands. Expecting the white frame, I was more than chuffed to see the dazzling brown and gold paint scheme. Nothing could stop me now…

My cranks had arrived at William’s house and it was a matter of bolting everything together. Except… the bottom bracket was still on backorder, but on its way. A few days later it arrived, and after some fiddling with the Di2 wiring in the days previous, we were ready to install the cranks. Now, you’ve already seen the above image and have recognised that’s not an Easton crank but an Ultegra. The 30mm spindle of the EC90, when sheaved in its plastic sleeve, left little room in the BB shell for the Di2 wiring, but would spin freely without it, but I feared would rub the Di2 wiring and eventually cause a short circuit (is that a thing with electronic wiring?). Not too much of a problem, but the fat carbon 175mm crankarms were now hitting the stays, even with the mods done by Jaegher. I played around with spacers, which would give clearance but a terrible chainline, and even had a smaller chainring sent over but to no avail. I tried a Shimano 2x crank of William’s and it was fine. (Hit me up if you’re after a bargain EC90 crankset!)

By this time I had been at it over a week, and was riding William’s Focus Mares CX bike and resigned myself to the fact that I wouldn’t be riding my new bike for the Bootlegger, but might sort something out before my month in Flanders was up. Eventually I gave up on that notion and started to source a crank back in NZ with the plan to complete the build where I had my own tools and access to whatever I might need. Disappointed I didn’t get to christen the bike on its hallowed home soil, I packed up and did the praying that it would actually make it back to Kiwi terra firma. The feeling one gets when your bike bag emerges from the baggage hold is one of the best feelings… unpacking a damaged bike is not. A few chips and rubs but nothing bent or broken is a win in the air travel lottery.

A neat little Chain Keeper from Paul Component is added insurance for the already excellent retention of the NZ-made Revolution Components 40t chainring. Yes, I know the chain is back-to-front, an oversight after some fettling… it didn’t get ridden (far) like this!

To make absolutely sure there were going to be no more crank/chainstay issues I went a bit shorter with 172.5mm arms, and added a 40t narrow/wide ring from Christchurch’s Revolution Components. Everything spun smoothly after some more trial and error spacing of the BB cups, and we had a bike at last. The first proper ride went off without a hitch, and the relief was trumped by the pure quality of the frame’s feel. The same incredible smoothness of my road bike was there, and the same perfect fit as well. All the qualities of steel that I love are all present, and it has become my favourite ride by far.

The ability of this bike to go just about anywhere makes me think if I was to only own one bike, it would be this or a bike of similar ilk. It’s taken on all sorts of terrain including road rides, gravel, and muddy and rooty singletrack, where it makes you feel like John Tomac in the early 90s!

The WTB Byway tyres might look limited, but they are super impressive even on slick mud and roots. Hunt’s Adventure Sport 650b wheels have been super-reliable on several bikes now, staying true and running smooth with great durability.

Having run fi’zi:k Aliante saddles on my road bikes for a long time, it had to be the same here. A Versus model has a bit more padding for the rougher terrain this bike sees, and the clip-in seatbag keeps the vital spares handy.

An alloy R3 bar was preferred over the carbon R1 I run on my road bike, mainly for durability over rough roads. The painted ENVE carbon stem might be a tad too long, but I just can’t take it off yet because of how hot it looks!

Again, fi’zi:k is my choice for tape, with 3mm thick Performance Soft Touch keeping it comfy and durable under hands.

The brief for this bike has been carried out to a tee, despite the setbacks along the way. It’s a do-everything bike that will see its share of adventures from gravel racing to overnighters and more. Having the ability to carry stuff was high on my list, and I enlisted my long-time hometown friend Kedan aka the Bike Bag Dude to whip up a camera bag so I could properly document such rides. There will be a half frame bag coming to complement the Barrel Roll and Gas Tank shown here, and a Revelate seat bag out back from Cyclewerks helping out also.

Having two sets of wheels makes this bike a true Swiss Army knife machine though. With the 650b Hunts and WTB Byways it can take on most terrain, and I can even swap out the tyres for a more aggressive mountain bike tread up to 2.1 wide if I really want to get Tomac on it. The Campagnolo Zonda DB 700c wheelset gives me more options, like these 32c Terravail Galenas for more road and fast gravel riding, or a road slick, or up to a 42c tread for chunkier gravelling. Mixing up cassettes adds to the possibilities, and I have a 11-36 and 11-42 to play around with for a slew of combinations.

I’ve alway been a proponent for not mixing Italian and Japanese parts, but in the name of multiculturalism (and ultimate versatility) the Zonda DBs are a no-brainer. They look fantastic and are impressively stiff, and of course have the trademark smooth running traits of all Campa hubs.

Campa’s iconic G3 spoke lacing system finds its way onto the front wheel as well as the rear on the Zondas.

Shimano Ice Tech Freeza rotors claim to keep things cool under braking. I just think they look cool as well.

After all the time and setbacks along the way from concept to inception, I couldn’t be happier with the Interceptor. I have a bike that fits me perfectly, both in the physical sense but moreso in the spiritual one. It is the bike that I envisaged and while some changes were necessary from the the original idea, it’s arrived at a point that I think is even more suitable for what I want to do with it, and lots of things I’d never thought I could.

The process of a custom frame build is a fulfilling one, being able to discuss the nuances and needs with the people building it for you is something not many will experience, but one I highly recommend. I’ve arrived at the point where I now have two forever bikes, and don’t have to worry about market trends or obsolescence as a well-made steel frame never goes out of style and can be repaired and repainted if need be. And the ride quality is something special.

Huge thanks to Kurt and Diel at Jaegher for their expert advice, building skill and patience, and for making two dreams come true for me! And to everyone who helped with the build:

Nicolo at fi’zi:k Italy.

Joshua at Campagnolo Italy.

Fraser and Harley at Shimano NZ.

Bryce at Cyclewerks NZ.

Clayton at WTB USA.

Hamish at Hunt Wheels Australia.

Kedan at Bike Bag Dude Australia.

Richard at Revolution Components NZ.

Travis at Paul Component USA.

Matt at Easton USA.