Landed: WTB HTZ i30 EMTB Wheelset

Let’s face it, the electric bike, in all its forms, has saved the bike industry. For now. E-bikes created a whole new segment for manufacturers to develop products for, and they had a whole new audience to cater to. In the mountain bike world especially, new sub-cat products were actually useful and not just a marketing gimmick, as stuff really does wear out more quickly, due to greater loads on components such as drivetrains, heavier bikes, and the extra amount of time riders spend lapping the local trails.

Just as downhill bikes require burlier bits compared to a trail bike which needs more grunt than an XC bike and so on, the EMTB needs even more sturdy parts. There’s no doubt a EMTB ridden hard will chew through chains, cassettes and wheels faster than an acoustic bike using the same bits. But it’s not just a matter of making everything thicker and heavier, as the same riders don’t want to be lugging an extra chunk of weight around if they can avoid it.

My own bike came with some pretty average ‘house-brand’ wheels, same as found on their standard bikes. When I decided to try a mullet set-up, I bought the cheapest name-brand 27.5 rear wheel I could find, in case I didn’t like the party out back business up front caper. I did. The wheel had too few spokes, a mid-range hub and a great price! And it’s been a better performer than expected. The biggest issue has been a splitting at the join, allowing sealant and air to escape, remedied (temporarily) with some deft placement of tubeless tape up the inside of the walls. So I was more than fortunate to have a crack at these new E-specific wheels from WTB, a brand whose wares I’ve had good performance and reliability back in my acoustic days.

While these are essentially ‘mass-produced’ wheels, they are all built by hand in the USA and Italy, and you get the luxury of speccing exactly the combos of size, hub standards etc. I stuck with the Mullet option, coz I’m a party boy at heart. For the hub I’m loathe to ever use anything but a HG body, as 11 speeds is all I need and they are easy to find, work on and are not restricted to one cassette brand. I’ll be using the new Shimano Link Glide 11 speed cassette with these, and they obviously believe the HG standard is the best option for EMTBs as they don’t offer a spline version yet.

The rims are what takes the heat of 25kg of motorised bike being slammed, hucked and dropped repeatedly, so the i30 indicates an internal width of 30mm. Not just wider, but thicker too, with beefed up walls 20% thicker than their KOM Tough endro-specific rims. Not carbon, obviously, alloy rules this world.

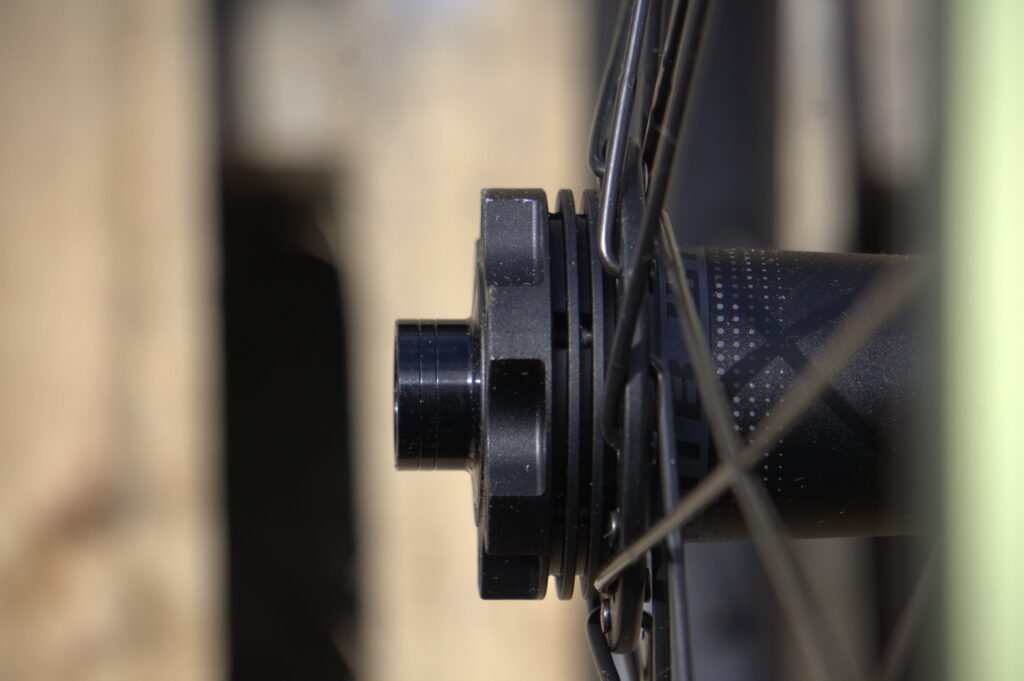

HTZ hubs feature a heat-treated steel freehub body, which eliminates gouging and prevents pawl socket failure under load. The new hubs feature a 6-pawl ratchet system with simultaneous engagement of all pawls to distribute pedaling forces more evenly and improve reliability on bikes with high-torque motors. Double-stacked, sealed Enduro bearings at the inboard end of the driver body further improve durability and extend bearing life.

According to the press release, WTB tested these against several leading brands’ E-specific hubs with the competitors’ hubs failing at 2,000 start/stop cycles, while HTZ hubs endured 40,000 cycles. Mainly due to the others just slapping on a steel freehub body onto their burliest non-E hub, whereas “every aspect of the new HTZ hub is specifically designed to withstand the additional torque and wear of e-bikes.”

This I really like: “HTZ hubs also feature a heat sink behind the 6-bolt rotor mount to improve heat dissipation by up to 10% on long descents, allowing you to descend with confidence despite the extra weight of an e-bike.” Hopefully I won’t chew through as many brake pads now, even the ones that are supposed to be E-friendly.

WTB also increased the outer diameter of the rear axle sleeve to 17mm (compared to a traditional 15mm sleeve), which increases performance and durability while remaining compatible with traditional 12mm thru-axles. This reduces axle flex while cornering and pedaling, which results in improved ride quality and bearing longevity.

The spokes are offset 6mm as explained here:

Asymmetric spoke offset helps balance spoke length and tension to create a more stable wheel while a symmetric outer rim profile distributes impact forces evenly through the rim.

Sounds legit.

The HTZs come ready to mount your rubber to, with tape and valves already installed. Nice.

HTZ tubeless-ready wheels feature our unique Solid Strip, which is a durable nylon strip that lies between the rim and tubeless tape to prevent tubeless tape from pushing into the spoke holes and therefore ensures a smooth interface between the tire and rim.

The smooth surface makes it easier to mount a tire by preventing air from escaping around the bead at each spoke hole indentation during inflation. Solid Strip also protects the airtight system from puncture in the case of a broken spoke.

HTZ wheels feature thick 2.3/2.0mm single-butted spokes to increase wheel stiffness and durability, with the thickest section at the hub to counteract the higher braking forces and increased motor torque of an e-bike.

Not built by robots. Fuck AI, these are made by AL. I really hope that’s short for Alan, or Big Al… either way, I’ll take human hands over artificial ‘intelligence’ every time.

I haven’t tried WTB’s sealant before, so will be interested to see how it compares to my usual market-leading brand.

If they’re good enough for one of my favourite ‘real’ mountain bikers of all-time then they will probably last a hacker like me for a very long time indeed.

Let’s see how these stand up, and roll around, over the next few months. Keep your eye on our Instant-thingy for updates and a full review right here on-site.